[Woodporterhouse] must deal with regular power black outs in his area. He recently converted a rack-mount uninterruptible power supply to feed a portion of his mains wiring. This one is not to be missed, since he did such a great job on the project, and an equally remarkable job of documenting it. It’s one of the best examples we’ve seen of how to use Imgur as a project log.

The UPS still needs to have a case, but it doesn’t need room for batteries as he’s going to use a series of high-end sealed lead-acid batteries. So he cut down the enclosure to about half of the original size. That’s it mounted just above the new batteries. For this to work you need some type of transfer switch which can automatically patch between incoming line voltage, and the battery backup. He already had one of these switches in place for use with a generator, that’s it in the upper left. The entire system powers a sub-panel responsible for his essential circuits — the electronics in the home and a few lighting circuits (we’d assume this includes utilities like the refrigerator).

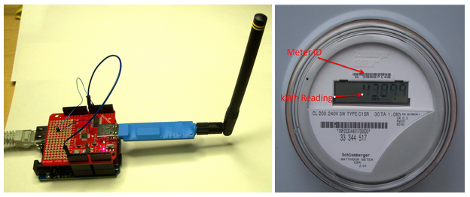

One really great feature that the reused UPS brings to the project is a monitoring card with a NIC. This way he can check the server to see if the UPS is being used, and how much of the 14 battery life remains.

[Thanks Ross via Reddit]

Recent Comments