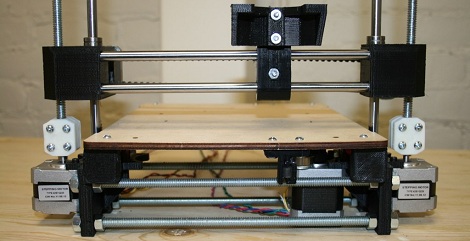

If you’ve never felt at home with a piping bag in your hands this chocolate extruder will come to your rescue. It can replace the plastic extruder head on your 3D printer (RepRap, Makerbot, most 3-axis CNC machines, etc.), letting you turn your digital creations into decadent reality.

The head uses a progressive cavity pump to feed the chocolate from a reservoir through the printing nozzle. It’s important to keep the chocolate warm or it will set up so when [Tomi Salo] designed the print head he included a heat shroud through which warm air can be circulated. He uses a shoe dryer to source the hot hair which is patched into the heat shroud with a length of tubing.

This extruder can be 3D printed but be careful what material you use. [Tomi] mentions that PLA is ‘sort of food-safe’ but ABS is not. We wonder if the design could be altered for milling out of aluminum or stainless? At any rate, if you’re going to give it a try you might find [Tomi’s] advice on working with chocolate useful.

[via @clothbot]

Recent Comments