When [Soo-Hyun]’s friend had an Apple Macbook Pro battery that began to swell, his friend did the reasonable thing and donated it to be used in a robot. Now [Soo-Hyun]’s kiwi drive robot is powered by a gigantic LiPo battery, giving it a huge range and a very fast top speed.

The defunct laptop battery that formerly powered a 15″ macbook pro is three battery packs of two cells in parallel, delivering 12.6 Volts. To get the power to the robot, [Soo-Hyun] etched a simple PCB that fit into the slot in the battery. A little bit of soldering later, and mounting the battery as a shark fin because of the 8×8 inch limitation of maze-solving robots, the power plant was complete.

Using a bulging LiPo battery probably isn’t the smartest idea (listen for the great line, “it got the camera and my face” at 4:08), but as long as [Soo-Hyun] keeps an eye on the battery as it’s charging, it should be alright.

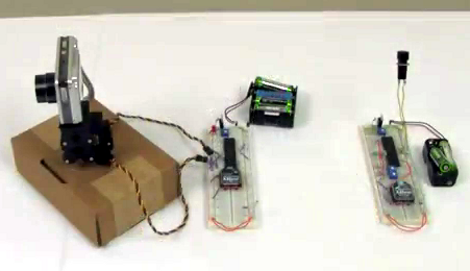

Check out the video of the robot zipping around on 12.6 Volts after the break.

Recent Comments