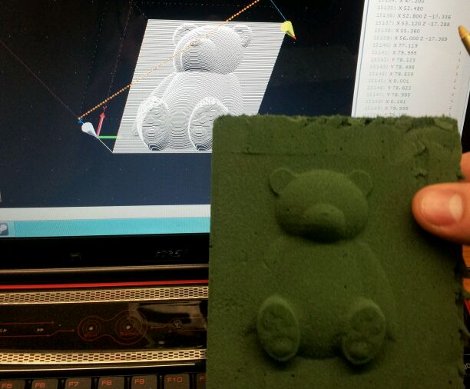

[Roy] is getting to the end of his second CNC mill project and finally seeing some results. Here you can see a bear he milled in some floural foam.

The project started out as an Arduino-based pen plotter. It move the pen along one axis, and the drawing surface along another, with the third axis allowing the pen to be lifted and repositioned. With that in his back pocket he went all out and began what he calls the Mark II. He used T-slot aluminum for the frame, which really helped when it came to aligning the linear rod supports for each axis. After a lot of drilling, and tapping he managed to bring each axis on line one at a time. A pre-fab CNC driver kit drives the stepper motors, making them groan as they do their work. hear it for yourself in the test video after the break were the machine is first tested as a pen plotter.

http://www.youtube.com/watch?v=n7DSxM3kt8k

floral

What software did you use to generate the G-code?

I wished I could see a video of the CNC milling process.

Well I was working on it at the time but for some reason one of the other makerbot stepper drives went kaboem when running an destroyed part of the controller. So I’m still waiting on 2 new chips so I could fix it. But everything will be explained in my next part of the build log.

I subscribed you on youtube anyways 😉

Well I was working on it at the time but for some reason one of the other makerbot stepper drives went kaboem when running an destroyed part of the controller. So I’m still waiting on 2 new chips so I could fix it. But everything will be explained in my next part of the build log.