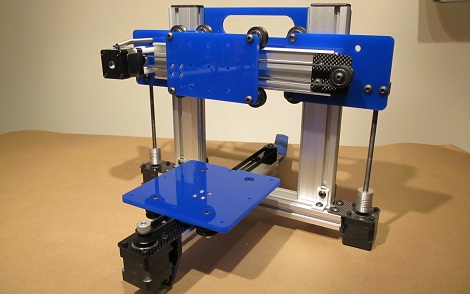

What would you do if you wanted to demonstrate a linear bearing system? If you’re like [Bart] the obvious solution is building a tiny little 3D printer. [Bart]’s Quantum ORD Bot is constructed out of a previous project of his, the MakerSlide linear bearing system.

The idea of a printer made out of MakerSlide materials came from [Bart]’s invitation to ORD Camp. The fact that this build went together in about 5 hours speaks volumes about the simplicity of the MakerSlide system. Right now, the printer is designed for NEMA 14 motors, but for larger builds there’s plenty of room for the larger NEMA 17 stepper motors. [Bart] put up a build log for his printer up on the buildlog.net forums.

The MakerSlide system has already been used in an open source laser cutter project, but [Bart] really just wanted something to demonstrate his linear bearing system. We like the bot anyway; not enough stuff is made out of aluminum extrusion these days.

[Bart] is going to be showing off his bot at the Chicago hackerspace Pumping Station: One tonight, February 8th. Stop by and check it out. Snap a few pictures for us and we’ll put them up.

EDIT: [gigawatts121] was kind enough to send in a picture of the printer at Pumping Station: One. There’s also a video of a calibration cube being printed courtesy of [David] in the comments. Check that out after the break.

[youtube=http://www.youtube.com/watch?v=gP2ebXlK3Ck&w=470]

It seems to me like the build itself has taken 5 hours. It still need electronics, extruder and so on. Five hours for the build itself is rather impressive though and i’d love to see the quality of prints.

that’s a really cool looking machine.

five hours is OK (or even too much) if you already have all parts at hand… it sure does look lovely 🙂

It looks like a really sturdy little piece of kit. It also looks quite simple. I wonder what the cost to build would be. (Including electronics and extruder).

The five hours included the time to design, fabricate the parts and assemble. The picture represents what was done after those 5 hours.

It is now fully complete after a few more hours of work. You can see updated pictures by following the links.

Aw man, I remember the Makerslide article. Shame the kickstarter ended just after I got my degree or I’d have absolutely backed that. When is the shop supposed to open?

You can find the maker beam over at sparkfun here: http://www.sparkfun.com/products/10540 or on it’s own web site here: http://www.makerbeam.eu/

Maker beam is not the same as Makerslide. Makerslide is a 20x40mm Al extrusion with rails build in so that it can be used in a linear bearing system. Maker beam looks to just be aluminum extrusion.

There is a store for the Makerslide http://store.makerslide.com.

Unfortunately, I do weekly releases of as much as I can possibly ship and it sells out within a few hours. Each week I ramp up the quantities as I get the process more dialed in.

Thanks for the info. My brain’s buzzing already.

Honestly, that doesn’t sound unfortunate at all. In fact, if I recall my economics class correctly, you should look at possibly increasing your prices. Ideally, you want to sell out just as you get the next week’s batch of MakerSlide in stock.

If this sounds risky, it’s because it is. CONSULT ACTUAL MARKETING AND ECONOMICS PEOPLE BEFORE YOU TRY THIS.

Looking at pricing, you currently have stock for $11 per meter, which is a pretty good price(Not as good as earlier this morning when I dropped a decimal and thought it was $1/meter), especially if you’re selling out within hours. The shop also says there’s a $1.25 cutting charge per segment, and minimum segment length is 10cm.

That means the actual price for the first 10cm ordered is $0.0235 per millimeter, with average price going down as the customer orders longer pieces. I’d look at absorbing the cutting charge into the unit price, and mark it up just a little to $0.025 per mm(or 25 cents per centimeter, sold in 1mm increments).

AGAIN, CONSULT REAL EXPERTS BEFORE YOU TRY THIS. As you know, customers don’t tend to like price hikes, and I understand that you’re probably targeting cheaper customer demographics. If it works, however, you stand to increase your profit margins significantly, which may enable you to purchase more manufacturing equipment down the road, at which point you could again begin reducing stock price. Remember, for maximum profit efficiency, you want to sell out of stock just as you run off another batch.

One good way to ease customer reaction to price hikes is to offer temporary discounts. Perhaps a half-off discount for pieces greater than a certain minimal length, or offer discount vouchers to some of your more regular customers.

Or maybe he can just keep ramping up production and supply more for the demand assuming it’s already making a reasonable profit. He sells more, makesmore, more get their hands on it. everybody wins so long as there is demand.

Raise prices too high and other people will invest in an aluminum die and contract an aluminum extrusion company to make them to sell at a lower price.

Nova: If he’s selling out in about 6 hours, then demand is NOT a problem. My sister(who has more economics classes under her belt more recently than I do) agrees that if you’re selling out in about 1/28 of a week, the right thing to do is raise prices. It’s not going to stop him from ramping up production. In fact, it’ll make it easier to ramp up production because as I said, the extra profits can be put into additional manufacturing equipment. Prices will eventually go back down, supply will go up more quickly, everyone benefits faster. The problem is not insufficient supply, the problem is that he has WAY too much demand, and the result is that he’s making significantly less than he could be.

Hackerspacer: If you look closely, I have that exact warning in my post, hence why I have two VERY LARGE ALL-CAPS WARNINGS to check with people who actually make their livings off of economics and marketing.

I’ve been following Makerslide since the kickstarter and can’t wait to actually be able to buy things from there!

That looks the business – simple, rock solid and easily scalable – how much for a kit?

Is it bad that my first reaction to the image above is “oooh, that’s cute!”?

Thopter – the more I look at it, the more I like it – elegant, simple based on proven, well thought out engineering – I have a Prusa frame on my desk in front of me, almost mocking me with the calibration man-hours to come – this looks SOOO much more straightforward – and target price of $200 for kit including the motors seems more than reasonable.

Would agree with other comments on the buildlog site – to expand the print area to equal(or more) that of Mendel variants wd be good.

Yep, how about that: – Q for bdring – what mounting options are there for extruders? – will it take a Wade’s?

oh – link slightly screwed, but gist got, innit

I have made it compatible with the MagerGear Plastruder and the Makerbot MK7. Someone is going to give me a Wade’s tonight at PS1 that I can design in.

Great work – Well Done.

I saw it print it’s first print today at Pumping Station One, a Chicago hackerspace.

[youtube http://www.youtube.com/watch?v=gP2ebXlK3Ck&w=560&h=315%5D

YouTube video:

http://youtu.be/gP2ebXlK3Ck

It prints very quiet. What you hear in the background of this video is actually another printer about 10′ away from this one.

Her is an image from the 20mm calibration file.

Uploaded with Skitch!

Here is the ORD Bot running at 160 mm/s

http://www.youtube.com/watch?v=SFtAW7apS0E

I want one. Are you selling kits yet?

You can reserve a kit over at the MakerSlide store.

http://store.makerslide.com